Volvo is poised to make a significant impact on the electric vehicle landscape with the impending launch of its new midsize SUV, the EX60, slated for an official debut on January 21st. This highly anticipated model promises to shatter previous benchmarks for Volvo EVs, boasting an impressive projected range of 400 miles (approximately 810 kilometers) under the rigorous WLTP standard. This substantial leap in electric range positions the EX60 to compete directly with, and in some cases surpass, the capabilities of existing and upcoming electric offerings, including Volvo’s own ES90 sedan, which is expected to achieve an even more remarkable 434 miles of range. A key enabler of this enhanced performance is Volvo’s pioneering adoption of its novel megacasting production process, a significant advancement designed to streamline manufacturing, reduce vehicle weight, and ultimately contribute to improved efficiency and sustainability.

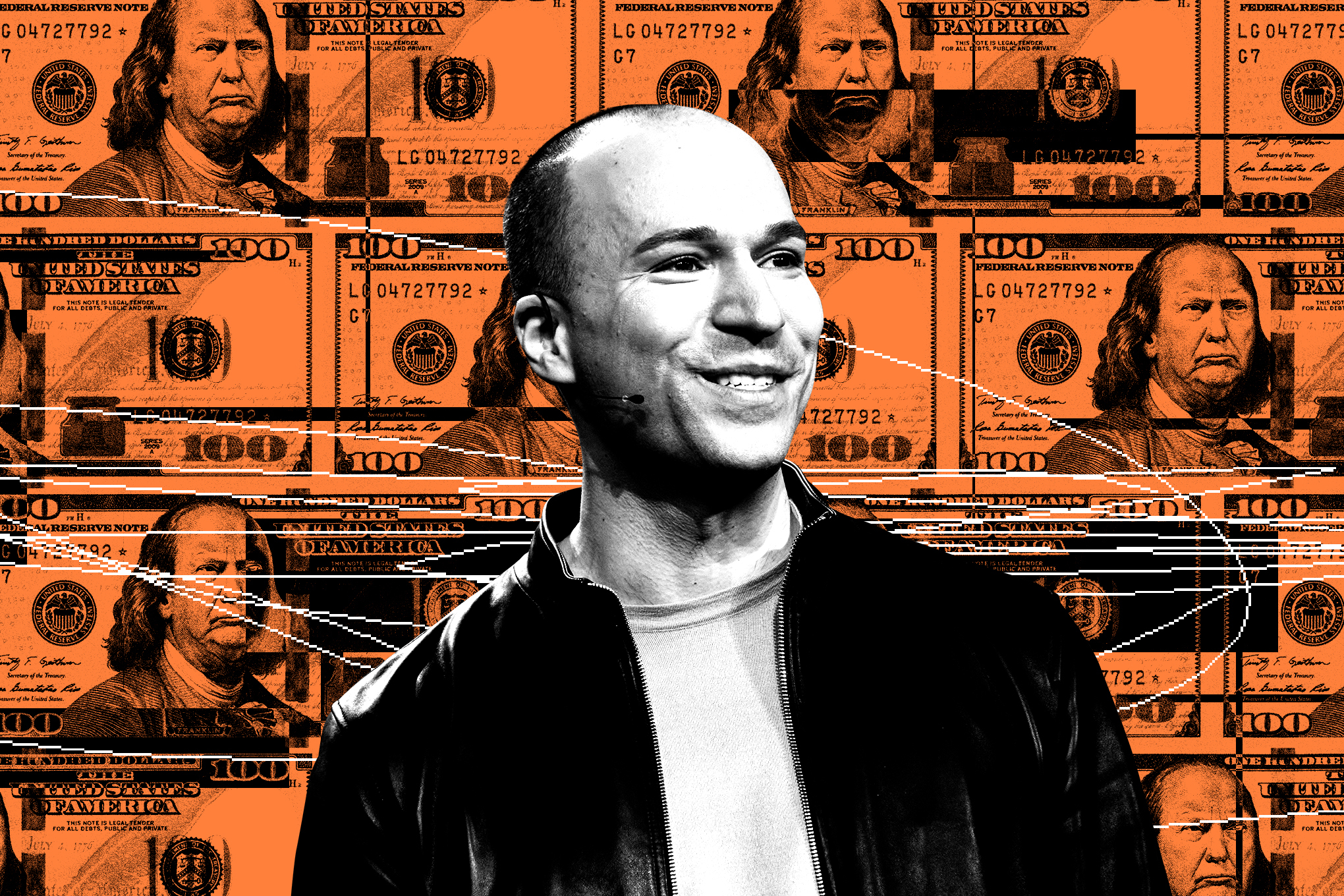

The strategic imperative behind the EX60’s development, as articulated by Akhil Krishnan, head of program management for the EX60, was to engineer an electric vehicle that fundamentally eliminates compromises for the consumer. "Our objective was to create an electric vehicle with no compromises," Krishnan stated. "Choosing to drive electric should not necessitate a trade-off in performance or convenience, and this principle was paramount throughout the EX60’s development." This core philosophy directly addressed the lingering consumer concern of "range anxiety," a significant barrier to widespread EV adoption. Volvo’s ambition for the EX60 is to transition this apprehension into a state of "range comfort," where the vehicle’s extended travel capability renders charging stops a secondary consideration, akin to how prospective buyers of internal combustion engine vehicles do not typically prioritize the fuel tank’s capacity as a primary decision-making factor.

Beyond achieving an exceptional driving range, the engineering team placed a critical emphasis on optimizing the EX60’s charging speed. Extensive market research and direct customer feedback revealed that a common pain point for existing EV owners involved the significant time commitment required for recharging, with many experiencing waits of 40 minutes or more. Volvo’s vision for the EX60 is to seamlessly integrate charging into natural human pauses in a journey. The goal is for the vehicle to replenish a substantial amount of its energy within the timeframe of a brief stop, such as grabbing a coffee or utilizing restroom facilities, thereby minimizing disruptions to travel plans.

This ambitious charging objective is made attainable through the EX60’s groundbreaking 800-volt electrical architecture, a first for Volvo vehicles. This advanced architecture positions Volvo to emulate the success of other automakers, such as Hyundai and Kia, who have leveraged 800-volt systems to offer rapid charging capabilities and stimulate demand in a fluctuating EV market. The EX60 is engineered to achieve an impressive 10% to 80% charge in a mere 19 minutes when connected to a 400kW DC fast charger. Furthermore, a mere 10-minute charging session is projected to add approximately 168 miles of range, a significant boon for long-distance travel and alleviating concerns about extended stops.

While the proliferation of 400kW charging infrastructure, particularly in certain regions like the United States, remains an evolving landscape, Volvo is committed to ensuring robust charging performance across a spectrum of charging stations. Krishnan emphasized that the EX60 is designed to deliver exceptional charging efficiency not only with the highest-power 400kW chargers but also with more commonly available 250kW units, thereby broadening its practical usability.

The EX60 is constructed upon Volvo’s proprietary SPA3 platform, an all-electric architecture meticulously designed from the ground up without the inherent limitations or compromises associated with adapting legacy internal combustion engine platforms. Notably, the EX60’s enhanced range is not attributed to breakthroughs in battery chemistry; it utilizes the same established nickel-cobalt-manganese chemistry found across Volvo’s electric vehicle portfolio. Instead, the gains are primarily realized through significant advancements in manufacturing processes. The innovative megacasting technique, which involves the production of large, single-piece structural components, plays a crucial role in reducing the overall weight of the vehicle. Coupled with the integration of a structural battery pack, this approach enhances the vehicle’s structural integrity while simultaneously contributing to weight reduction. Furthermore, the inclusion of advanced battery preconditioning technology ensures that the battery is maintained at its optimal operating temperature, facilitating sustained high-speed charging and maximizing efficiency.

The adoption of the new SPA3 platform yields substantial benefits beyond weight reduction. It also translates into significant cost efficiencies at the component level, with Volvo anticipating savings in the range of 20% to 35%. These manufacturing cost reductions are instrumental in Volvo’s strategy to position the EX60 with competitive pricing, aiming to align its cost with comparable gasoline and plug-in hybrid alternatives. Preliminary indications suggest that the EX60 will be priced in proximity to the current XC60 plug-in hybrid, which has a starting price point in the vicinity of $63,000.

Reinforcing its commitment to long-term reliability and customer confidence, Volvo is introducing an expanded global 10-year battery warranty for the EX60, covering up to 240,000 kilometers. This extension from the previous eight-year coverage underscores Volvo’s profound confidence in its in-house battery development and manufacturing capabilities.

The EX60 is also set to feature a suite of advanced functionalities, including vehicle-to-home (V2H) and vehicle-to-grid (V2G) capabilities, which will be offered as standard equipment across all markets and trim levels. This forward-thinking integration highlights Volvo’s proactive engagement with the evolving energy ecosystem. The company has already established a strategic partnership with Vattenfall, a prominent Swedish energy provider, to explore the potential of Volvo EVs, including the EX60, to contribute to grid stabilization and load balancing. This initiative positions Volvo at the forefront of vehicle-as-an-energy-resource solutions.

From a strategic perspective, Krishnan views the EX60 as a pivotal addition to Volvo’s comprehensive electric vehicle strategy, filling a crucial market segment. The EX60 is designed to be a more accessible family SUV compared to the larger, three-row EX90, which carries a price tag exceeding $80,000. "This car addresses a very substantial addressable market," Krishnan commented, emphasizing the broad appeal and potential sales volume for a well-equipped, premium electric SUV at a more attainable price point.

Production of the EX60 will commence at Volvo’s established manufacturing facility in Gothenburg, Sweden, with initial production runs slated to begin in the first half of 2026. This strategic manufacturing location ensures adherence to Volvo’s stringent quality standards and facilitates efficient global distribution. The introduction of the EX60 represents a significant milestone for Volvo, signaling its continued dedication to advancing electric mobility through innovation in range, charging technology, manufacturing efficiency, and intelligent energy management.