In a significant announcement emerging from the heart of the technology world, a Finnish startup claims to have achieved a breakthrough in battery technology, potentially marking a pivotal moment for electric vehicles and beyond. This development, presented at CES 2026, introduces the "Donut Battery," a solid-state energy storage solution that is reportedly already in production, a stark contrast to the often-delayed promises that have characterized this field.

For years, the electric vehicle (EV) industry has been captivated by the promise of solid-state batteries. These advanced power cells, which replace the flammable liquid electrolytes found in traditional lithium-ion batteries with solid materials, are heralded for their potential to deliver a potent combination of enhanced safety, increased energy density, faster charging capabilities, and extended lifespans. However, the journey from laboratory concept to mass-market reality has been fraught with challenges, leading to a cycle of ambitious pronouncements followed by unmet deadlines and eventual industry skepticism.

A notable example of this pattern occurred at CES 2018, when Henrik Fisker, CEO of the now-defunct Fisker Automotive, proclaimed his company had unlocked the secrets to solid-state battery technology, with mass production slated for 2020. This ambitious timeline for the EMotion electric car ultimately proved unattainable, and the company eventually abandoned its solid-state aspirations. By 2024, Fisker Inc. had filed for bankruptcy, leaving many to question the viability of such revolutionary battery claims.

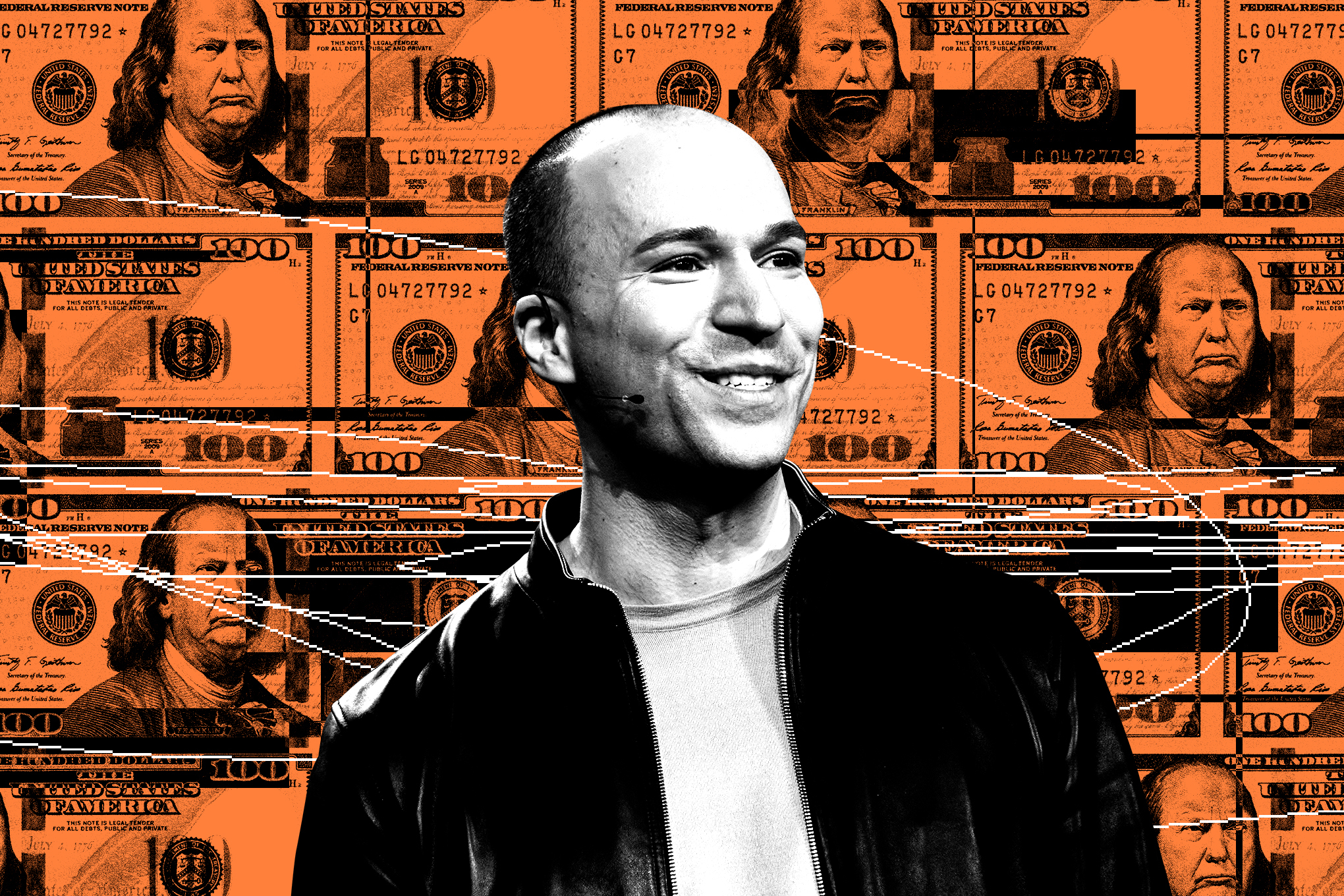

Against this backdrop of past disappointments, the unveiling of the Donut Battery by Donut Lab, an EV technology spin-off from Verge Motorcycles, carries a unique weight. Marko Lehtimaki, co-founder and CEO of Donut Lab, presented his company’s innovation not as a future aspiration, but as a present reality. This immediate availability, coupled with a suite of impressive performance metrics, distinguishes Donut Lab’s offering and warrants a closer examination of its potential impact.

The Enduring Allure of Solid-State Technology

The fundamental concept behind solid-state batteries has remained consistent for decades: replacing the liquid electrolyte with a solid medium that facilitates the movement of ions between the anode and cathode. This seemingly minor alteration holds profound implications. In conventional lithium-ion batteries, the liquid electrolyte is a significant contributor to safety concerns, posing a risk of thermal runaway and fire. Furthermore, the liquid medium can degrade over time, limiting the battery’s lifespan and charging speed.

Solid-state electrolytes, by their very nature, eliminate these inherent weaknesses. They are non-flammable, inherently safer, and more robust. This increased durability is expected to translate into a substantial increase in the number of charge cycles a battery can endure, extending the operational life of devices and vehicles significantly. Moreover, the absence of liquid components can enable more compact and lightweight battery designs, leading to greater energy density—more power packed into the same or smaller volume and weight.

Donut Lab’s Bold Claims and Performance Metrics

Donut Lab is asserting that its solid-state batteries are not only safer and longer-lasting but also more energy-dense and cost-effective to produce than current lithium-ion technologies. The company reports an energy density of 400 Wh/kg, a figure that represents approximately a 30% improvement over many contemporary lithium-ion battery packs. This enhancement translates directly into tangible benefits for electric vehicles, promising greater range from a battery of equivalent weight or the possibility of a lighter vehicle with the same range.

Crucially, Lehtimaki claims that the manufacturing cost of these advanced cells has actually decreased. This cost reduction is attributed to a simplified bill of materials, a statement that directly addresses one of the primary hurdles to the widespread adoption of solid-state batteries—their typically high production costs. According to Lehtimaki, the adoption of Donut Batteries by Verge Motorcycles for its TS Pro model has already led to a reduction in manufacturing expenses, a trend he anticipates will continue as production scales and more vendors adopt the technology.

The charging speed promised by Donut Lab is equally revolutionary. While the company targets a full charge in as little as five minutes for future applications, the current iteration for the Verge TS Pro achieves a substantial charge in approximately 10 minutes. This rapid charging capability would effectively eliminate one of the most significant barriers to EV adoption: the time required to "refuel" compared to internal combustion engine vehicles.

The longevity claims are also remarkable. Donut Lab forecasts an impressive 100,000 charge cycles before significant degradation occurs. This figure dwarfs the typical 1,500 cycles found in most EV lithium-ion battery packs. If realized, a 100,000-cycle lifespan would mean a battery that could easily outlast the vehicle it powers. Lehtimaki further suggests that such durable batteries could retain significant residual value after their automotive service life, potentially being repurposed for stationary energy storage applications like home batteries. While Verge Motorcycles has indicated a more conservative 10,000-cycle expectation for its initial application, even this represents a substantial improvement over current standards.

Addressing Thermal Challenges and Manufacturing Realities

Beyond energy density and charging speed, the thermal stability of Donut Batteries is highlighted as a significant advantage. Lehtimaki reports that the cells maintain nearly full capacity even at temperatures as low as -22 degrees Fahrenheit (-30 degrees Celsius). This exceptional performance in cold weather conditions has profound implications for EV range and reliability in colder climates.

Furthermore, this thermal resilience is expected to significantly reduce or even eliminate the need for complex and energy-intensive active cooling systems. Neil Yates, founder and CEO of Watt Electric Vehicle Company, a platform manufacturer that utilizes Donut Lab’s hub motors and is exploring integration of the new batteries, commented on this aspect. He stated that the "no real active cooling requirement at all" for the batteries, thanks to their inherent thermal stability, would simplify vehicle design, reduce weight, and decrease the overall complexity of the EV’s thermal management system. This simplification contributes to further weight savings, a critical factor in EV efficiency and performance.

Donut Lab claims its solid-state batteries are currently in production at a facility in Finland, with an initial capacity of approximately one gigawatt-hour. The company expresses readiness to rapidly establish new manufacturing plants in the United States should there be sufficient demand from American automotive manufacturers. A key aspect of their manufacturing strategy appears to be the utilization of battery chemistry that avoids conflict minerals or materials subject to complex import/export regulations, suggesting a move towards more readily available and ethically sourced components. While Lehtimaki remained circumspect about the specific materials used, industry speculation points towards potential sodium-metal chemistries, which offer advantages in terms of cost and availability compared to lithium.

Navigating the Dendrite Dilemma and the Path Forward

A persistent and formidable challenge in the development of solid-state batteries has been the issue of dendrite formation. These microscopic, needle-like structures can grow from the anode across the solid electrolyte to the cathode, causing a short circuit and potentially leading to catastrophic battery failure and fire. Many major battery developers have struggled to overcome this hurdle. Lehtimaki attributes Donut Lab’s success in solving this "dendrite issue" to the agility and focus of a smaller, specialized engineering team. He posits that a more focused group, unburdened by the bureaucratic complexities of larger organizations, can iterate and innovate more rapidly, ultimately achieving breakthroughs where larger entities have faltered.

While the claims made by Donut Lab are undeniably compelling, the history of solid-state battery development warrants a degree of cautious optimism. The parallels to past ambitious pronouncements, including the mention of potential applications for smaller devices like smartphones, naturally invite scrutiny. However, Lehtimaki’s emphasis on immediate production and his avoidance of extended future timelines differentiate his company’s approach. The proof, he asserts, will be evident within weeks, not years. This directness offers a refreshing change from the protracted development cycles previously witnessed.

The coming months will be critical in validating these claims. The successful commercialization of Donut Lab’s solid-state batteries would not only represent a significant technological achievement but also catalyze a profound transformation across the automotive sector and potentially beyond. The implications for energy storage, from electric vehicles to grid-scale solutions, are immense, promising a future powered by safer, more efficient, and longer-lasting energy solutions. The world will be watching closely to see if this time, the solid-state revolution has truly arrived.