A recent comprehensive analysis suggests that a significant portion of the critical minerals vital to national security and economic stability could be sourced domestically from the overlooked byproducts of active United States metal mining operations, dramatically altering the nation’s reliance on global supply chains.

The quest for secure and sustainable access to critical minerals has emerged as a paramount geopolitical and economic challenge in the 21st century. These essential elements underpin the technological advancements driving modern economies, from renewable energy systems and advanced electronics to defense applications and medical innovations. Historically, the United States, despite its rich geological endowment, has become increasingly dependent on foreign sources for many of these strategic materials. However, groundbreaking research now illuminates a largely untapped domestic potential: the substantial quantities of critical minerals currently discarded as waste in existing U.S. metal mining and processing facilities.

The Overlooked Riches in Byproduct Streams

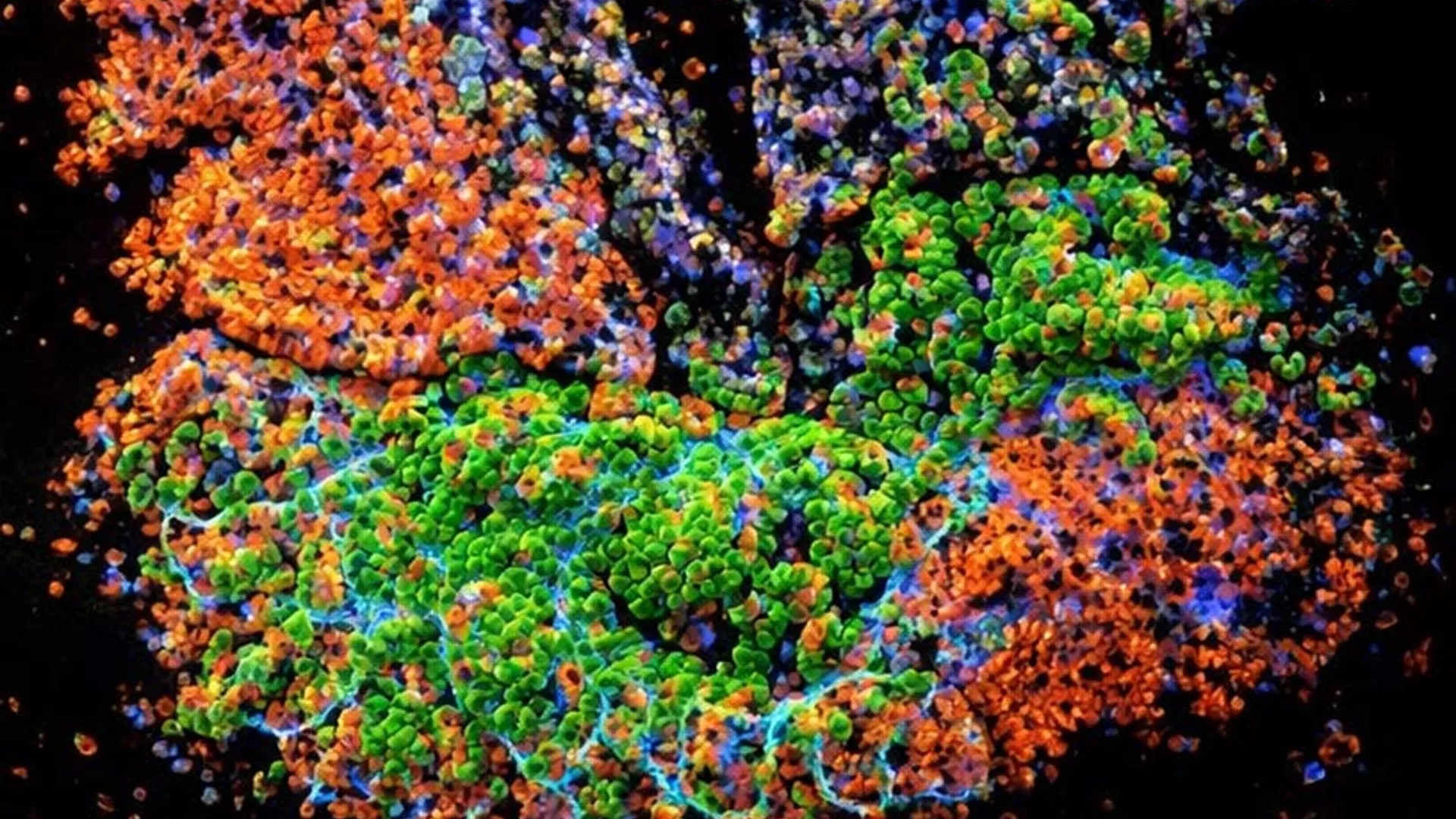

Critical mineral byproducts represent a unique category of elements that naturally coexist within ore bodies primarily targeted for the extraction of base metals such as copper, gold, zinc, or nickel. While the primary metals are the focus of current operational economics, these secondary minerals, though present in smaller concentrations, are intrinsically valuable. During the intricate processes of ore crushing, grinding, flotation, and smelting, these trace elements are typically separated from the target metals and often disposed of in tailings, the finely ground rock waste from which valuable minerals have been extracted. The new statistical inquiry, spearheaded by a dedicated research team, reveals that the purposeful recovery of even a fraction of these overlooked materials could fundamentally reshape the domestic supply landscape for a broad spectrum of critical minerals.

The findings are stark and transformative: theoretical modeling indicates that a recovery rate of 90 percent of these identified byproducts could potentially satisfy nearly all of the nation’s critical mineral requirements. More immediately impactful, even a modest one percent recovery rate would lead to a substantial reduction in import dependency for the majority of evaluated elements. This suggests that relatively incremental advancements in mineral processing technologies, coupled with strategic investment, possess the capacity to yield disproportionately large returns in enhancing domestic supply resilience.

Defining and Delineating Critical Minerals

Critical minerals are defined by their indispensable role in the economy and national security, coupled with a high risk of supply disruption due to limited domestic production, geopolitical vulnerabilities, or market concentration. The U.S. Geological Survey regularly updates its list of critical minerals, reflecting evolving technological needs and supply chain dynamics. This category encompasses a diverse array of elements, including but not limited to cobalt, essential for high-performance batteries; nickel, crucial for stainless steel and EV batteries; manganese, vital for steel alloys; lithium, the cornerstone of modern rechargeable batteries; tellurium, used in solar cells and thermoelectric devices; and germanium, integral to fiber optics and infrared optics. Rare earth elements, though not explicitly detailed in the source, also fall squarely within this critical classification, indispensable for permanent magnets in wind turbines and electric vehicle motors.

The pervasive application of these elements underscores their strategic importance. They are the invisible enablers of contemporary life and future innovation. Electric vehicles rely on lithium-ion batteries and rare-earth permanent magnets. Wind turbines harness energy with powerful magnets containing rare earths. Advanced semiconductors, the brains of all modern electronics, utilize materials like germanium and gallium. Solar panels convert sunlight into electricity with the aid of tellurium and indium. Beyond civilian applications, these materials are indispensable for advanced defense systems, from precision-guided munitions and stealth technologies to sophisticated communication arrays. Medical devices, aerospace components, and telecommunications infrastructure similarly depend on a secure supply of these often-obscure elements.

The global trajectory toward decarbonization and digitalization is driving an unprecedented surge in demand for these materials. As countries commit to ambitious clean energy transitions, the need for batteries, solar panels, and wind infrastructure will only intensify. Concurrently, the existing supply chains for many critical minerals are characterized by significant geographic concentration and susceptibility to geopolitical instability, trade disputes, and environmental regulations in producing nations. Developing new greenfield mines is a notoriously protracted process, often spanning decades from discovery to production, making the identification and activation of alternative domestic sources, particularly from existing operations, an exceptionally appealing and strategically imperative proposition.

Methodology: Uncovering Latent Value

To quantify this previously unmeasured domestic potential, the researchers employed a sophisticated analytical approach, integrating two distinct and extensive datasets. The first dataset meticulously cataloged the primary commodities produced at federally permitted metal mines operating across the United States. This provided a comprehensive operational footprint of the nation’s active mining sector. The second, equally crucial dataset comprised detailed geochemical assays, revealing the concentrations of approximately 70 critical minerals found within ore samples collected from various geological formations nationwide.

By judiciously correlating the active production data with the granular mineral chemistry data, the research team was able to construct an estimative model. This model allowed them to ascertain, with a high degree of precision, the quantities of each critical mineral that are currently being extracted and processed alongside primary metals, yet are not being recovered. Instead, these valuable byproducts are inadvertently diverted into mine waste streams, commonly known as tailings. The management of tailings represents a significant environmental and operational challenge for mining companies, requiring careful storage and long-term monitoring to mitigate potential ecological impacts. The prospect of recovering valuable materials from these streams offers a dual benefit: resource extraction and waste reduction.

A striking revelation from the study underscores the economic paradigm shift this approach could catalyze: in numerous instances, the recovery of less than 10 percent of these critical mineral byproducts would generate a total dollar value surpassing that of the primary metals currently sold by the respective U.S. mines. This finding profoundly challenges conventional mining economics, suggesting that what is presently regarded as an unavoidable waste product and a liability could, with the right technological and policy framework, be transformed into a principal economic asset, significantly enhancing the overall profitability and sustainability of mining operations.

Multifaceted Benefits: Economic, Strategic, and Environmental

The implications of recovering critical mineral byproducts extend far beyond mere economic gains, encompassing profound strategic and environmental advantages. From an economic standpoint, the creation of a robust domestic supply chain would stimulate investment in advanced processing technologies, foster job creation in specialized fields, and reduce the volatility associated with international commodity markets. It would also contribute to a more diversified and resilient industrial base, lessening vulnerability to external economic shocks.

Strategically, the reduction of import dependence is paramount for bolstering supply security across critical sectors such as energy, advanced manufacturing, and defense. Geopolitical shifts, trade protectionism, and international conflicts can swiftly disrupt global supply chains, jeopardizing the availability of essential materials. A domestic supply mitigates these risks, providing a stable foundation for innovation and production. This enhanced self-sufficiency is a cornerstone of national resilience and strategic autonomy in an increasingly complex global environment.

Environmentally, the benefits are equally compelling. The recovery of valuable minerals from existing waste streams fundamentally redefines waste management practices. By extracting useful materials, the volume and long-term environmental footprint of mine tailings can be significantly reduced. This not only lessens the burden of storing and monitoring vast quantities of waste but also potentially opens avenues for the reuse of processed materials in other industrial applications, such as construction aggregates, thereby fostering a more circular economy within the mining sector. Furthermore, increased recovery from existing operations could reduce the pressure to develop entirely new mines, minimizing the disturbance of untouched landscapes and associated ecological impacts. This approach aligns with broader sustainability goals and enhances the social license to operate for the mining industry.

Navigating the Challenges and Forging a Path Forward

Despite the immense promise, the realization of this potential is not without its challenges. The efficient and cost-effective recovery of critical minerals, often present in low concentrations within complex ore mixtures, necessitates advanced technological solutions. These include sophisticated hydrometallurgical or pyrometallurgical processes, innovative separation techniques, and potentially bioleaching methods. Implementing such technologies requires significant capital investment in new processing infrastructure and ongoing research and development to optimize efficiency and reduce operational costs.

Policy frameworks also play a pivotal role. Supportive government policies, including targeted research grants, tax incentives for domestic processing, streamlined permitting processes, and potentially demand-side mechanisms, are crucial to de-risk investment and accelerate deployment. As articulated by the researchers, the primary hurdle lies in transforming these theoretical possibilities into practical, scalable, and economically viable operations.

Nonetheless, the collective findings underscore a profound, largely untapped opportunity. Active U.S. mines are already extracting and handling the raw materials that contain the elements vital for the next generation of batteries, clean energy systems, and high-tech manufacturing. With concerted investment in research and development, strategic policy incentives, and a collaborative approach involving industry, academia, and government, these hidden byproducts can be transformed from discarded waste into a powerful, secure, and sustainable domestic resource, fundamentally strengthening America’s economic competitiveness and national security posture for decades to come. The paradigm shift from viewing these elements as mere impurities to recognizing them as strategic assets holds the potential to redefine the future of mining and resource management in the United States.