A significant scientific advancement has addressed a critical durability challenge in solid-state batteries, demonstrating how a novel silver-based surface treatment can dramatically enhance the resilience of solid electrolytes, potentially unlocking the full promise of safer, higher-energy-density, and ultra-fast-charging power sources.

The pursuit of solid-state batteries has long captivated researchers and engineers globally, driven by the profound advantages they offer over conventional lithium-ion technology. By replacing flammable liquid electrolytes with solid, non-combustible alternatives, these next-generation batteries promise inherent safety improvements, eliminating the risk of thermal runaway and fire. Furthermore, the ability to pair solid electrolytes with lithium metal anodes could unlock vastly superior energy densities, allowing devices to operate longer and electric vehicles to travel further on a single charge. Crucially, the solid-state architecture also holds the potential for dramatically faster charging rates, addressing a key consumer concern in the adoption of electric mobility. Despite these compelling benefits, widespread commercialization has been hampered by a persistent engineering hurdle: the susceptibility of solid electrolytes, particularly ceramic ones, to mechanical degradation. Over repeated charge-discharge cycles, these brittle materials tend to develop microscopic fissures and cracks that propagate, ultimately leading to battery failure. This structural weakness has represented a formidable barrier to realizing the transformative potential of solid-state technology.

However, recent investigations conducted by a team of researchers at Stanford University have yielded a promising solution. Building upon prior foundational work that meticulously mapped the formation and spread of nanoscale defects, dents, and cracks within solid electrolyte materials, the Stanford group has now unveiled a method to substantially mitigate this critical weakness. Their innovative approach involves a specialized heat treatment applied to an exceedingly thin layer of silver deposited onto the surface of the solid electrolyte. This treatment was found to impart a remarkable degree of resistance to mechanical damage, representing a pivotal step forward in the quest for durable solid-state batteries.

The findings, detailed in the prestigious scientific journal Nature Materials, illuminate the profound impact of this silver-enhanced surface. The treated electrolyte exhibited an astonishing fivefold increase in resistance to cracking induced by mechanical stress. Beyond merely strengthening the material against new damage, the protective coating also proved instrumental in curtailing the intrusion of lithium into pre-existing surface imperfections. This phenomenon of lithium penetration is particularly detrimental during rapid charging processes, where even minute surface flaws can rapidly expand into deeper, more damaging channels, irreversibly compromising the battery’s performance and lifespan. The ability of the silver treatment to counteract both the initiation and propagation of these destructive processes marks a significant leap in solid-state battery engineering.

Understanding the inherent fragility of solid electrolytes is crucial to appreciating the magnitude of this discovery. As explained by Dr. Wendy Gu, an associate professor of mechanical engineering and a senior author of the study, the solid electrolytes currently under development, including the widely studied ceramic variety, are inherently brittle. She draws a parallel to household ceramic items, noting that even seemingly pristine plates or bowls often possess minuscule, unseen surface imperfections. These microscopic flaws become critical vulnerabilities in the dynamic electrochemical environment of a battery. The challenge of manufacturing solid-state battery components entirely free of such defects is formidable. A typical solid-state battery comprises multiple layers of cathode, electrolyte, and anode sheets meticulously stacked together. Achieving absolute perfection across these layers during mass production would entail prohibitive costs and technological complexity, making it an economically impractical goal. Recognizing this industrial reality, the research team strategically shifted its focus from attempting to eradicate all defects to developing a robust, protective surface layer. Their findings suggest that even a minimal application of silver can provide a highly effective defense mechanism.

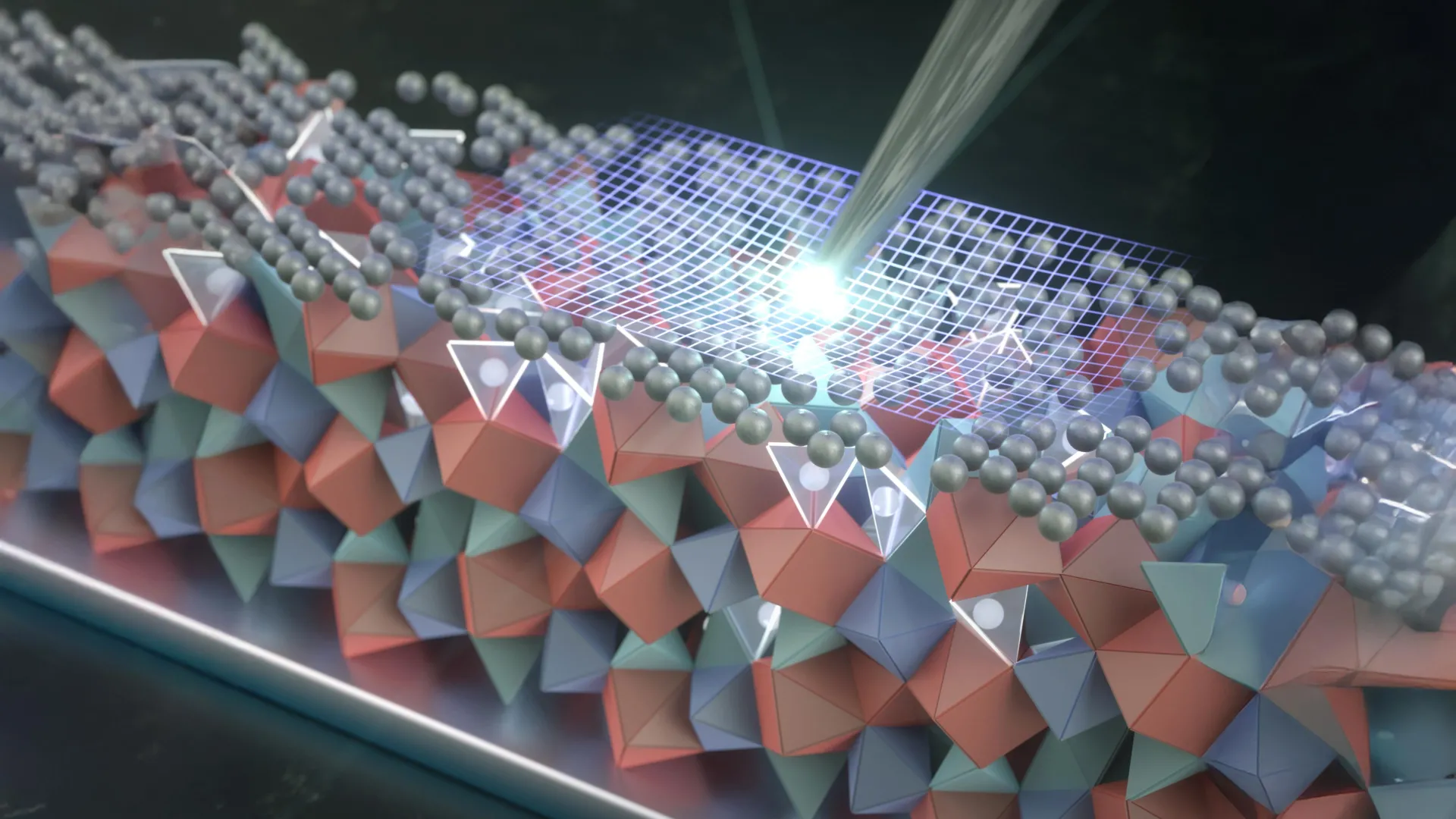

Earlier investigations by various research consortia had explored the application of metallic silver coatings to the same solid electrolyte material, often referred to as "LLZO" due to its elemental composition of lithium, lanthanum, zirconium, and oxygen. However, the Stanford team diverged from these prior efforts by employing a distinct form of silver: a dissolved, positively charged silver ion (Ag+), which has lost an electron. This subtle yet critical distinction proved to be the linchpin of their success. The researchers’ analysis indicates that these positively charged silver ions exhibit fundamentally different behavior compared to their metallic counterparts. Crucially, it is these Ag+ ions that are directly implicated in strengthening the ceramic structure and significantly reducing its predisposition to cracking. This targeted ionic interaction represents a more sophisticated approach to material modification than simply applying a metallic layer.

The methodology behind the silver treatment is remarkably precise and impactful at the nanoscale. The research team applied an ultrathin layer of silver, precisely 3 nanometers thick, to the surface of LLZO samples. These samples were then subjected to a controlled heat treatment, reaching temperatures of 300 degrees Celsius (572 degrees Fahrenheit). During this thermal process, individual silver atoms migrated from the applied layer into the outermost surface of the electrolyte material. Within the porous crystal lattice of the LLZO, these incoming silver atoms effectively displaced smaller lithium atoms. This intricate atomic exchange penetrated to a depth of approximately 20 to 50 nanometers below the surface, creating a reinforced zone. A pivotal aspect of this process is that the silver remained in its positively charged ionic state throughout, rather than converting into metallic silver. This ionic configuration is believed to be fundamental to the crack-prevention mechanism. Furthermore, in regions where nascent imperfections or tiny cracks already existed, the embedded silver ions demonstrated an ability to impede the ingress of lithium, thereby preventing the formation of detrimental internal structures that accelerate battery degradation.

Dr. Xin Xu, who spearheaded this research as a postdoctoral scholar at Stanford and is now an assistant professor of engineering at Arizona State University, emphasized the transformative nature of their findings. He stated that their investigation definitively demonstrates how nanoscale silver doping can fundamentally alter the initiation and propagation pathways of cracks at the electrolyte surface. This modification, he elaborated, yields remarkably durable and failure-resistant solid electrolytes, essential for the realization of next-generation energy storage technologies. Dr. Xu further highlighted the potential for broader applicability, suggesting that this innovative methodology could be extended to a diverse array of ceramic materials. The research underscores how ultrathin surface coatings can effectively enhance the ductility and stability of electrolytes, even under extreme electrochemical and mechanical stressors, such as the intense conditions encountered during rapid charging and significant pressure variations. This work was conducted in the laboratory of Professor William Chueh, a senior author of the study and director of the Precourt Institute for Energy within the Stanford Doerr School of Sustainability.

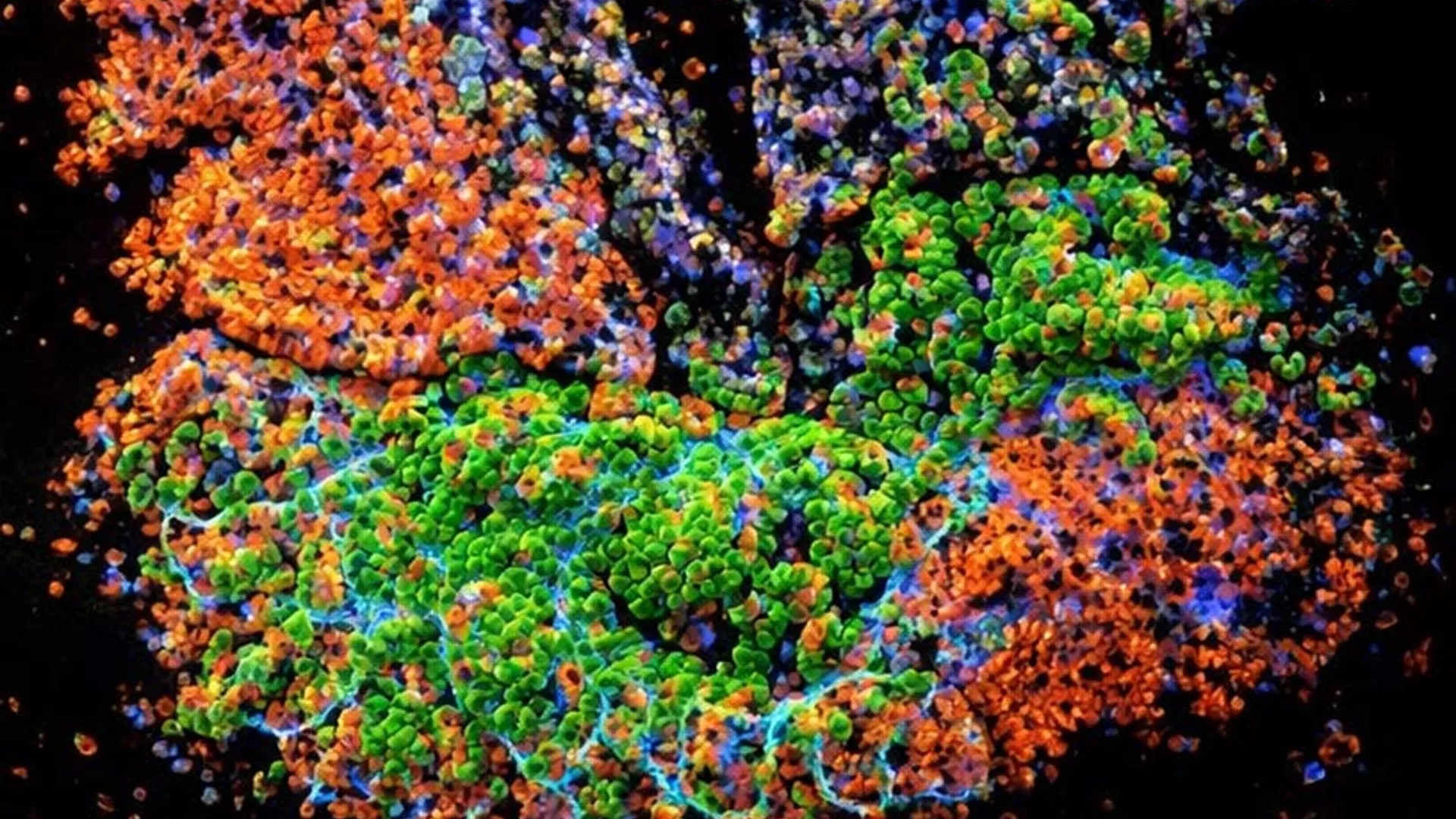

To rigorously quantify the extent of strengthening achieved by the treatment, the researchers employed advanced characterization techniques. A specialized probe, integrated within a scanning electron microscope, was utilized to precisely measure the force required to induce fracture on the electrolyte surface. The results were compelling: the silver-treated material exhibited an almost fivefold increase in the pressure tolerance before cracking, compared to untreated control samples. This quantitative validation provides robust evidence of the treatment’s efficacy and the significant improvement in mechanical robustness.

While the laboratory results are highly encouraging, the journey from scientific discovery to widespread commercial deployment often involves navigating complex engineering challenges. To date, the experiments have primarily focused on localized, small-scale areas of the electrolyte material, rather than integrated, full-scale battery cells. Consequently, critical questions remain regarding the scalability of this silver-based approach. Integrating this precise nanoscale treatment into large-format battery manufacturing processes presents a significant hurdle. Furthermore, assessing its long-term performance and durability over thousands of charging cycles, in conjunction with other battery components, is an essential next step. The true litmus test will be whether the enhanced resistance to cracking can be maintained over the extended operational lifespan expected of commercial batteries.

The research team is actively pursuing these next phases of development. Their current efforts are concentrated on integrating the silver treatment into complete lithium metal solid-state battery cells. This involves investigating how external mechanical pressure, applied from various angles, might further extend battery lifespan in a more realistic operational context. Concurrently, the researchers are exploring a broader spectrum of solid electrolyte chemistries, including sulfur-based materials, which hold promise for improved chemical stability when paired with highly reactive lithium metal anodes.

Beyond lithium-ion systems, the implications of this research could extend to other emerging battery technologies. Sodium-based batteries, for instance, could potentially benefit from analogous surface modification strategies. The development of viable sodium-ion technologies could alleviate growing supply-chain pressures associated with the increasing global demand for lithium, offering a more geographically diverse and potentially cost-effective alternative. The research also suggests that silver may not be the sole viable candidate for this strengthening mechanism. The team posits that other metal ions could potentially achieve similar results, provided their ionic radius is larger than that of the lithium ions they would replace within the electrolyte’s crystal structure. Early tests with copper, for example, demonstrated some positive effects, although it proved less effective than silver in the specific LLZO system studied. This opens avenues for exploring a range of alternative dopants, potentially leading to even more optimized and cost-effective solutions.

This seminal work, co-authored by Dr. Yue Qi, an engineering professor at Brown University, along with Stanford co-lead authors Teng Cui, Geoff McConohy, and Samuel S. Lee, and Brown University alumnus Harsh Jagad, represents a pivotal moment in solid-state battery research. By directly confronting and offering a compelling solution to the long-standing challenge of electrolyte degradation, this silver-enhanced strategy brings the promise of truly safe, high-performance, and fast-charging solid-state batteries significantly closer to reality, heralding a new era for energy storage technologies.