A pioneering development in acoustic physics has yielded a novel "phonon laser," offering an unprecedented capability to generate highly controlled mechanical vibrations at a microscopic scale, akin to orchestrating seismic events on a microchip. This innovative technology promises to fundamentally transform the design of future wireless electronics, enabling devices that are not only significantly smaller and more energy-efficient but also capable of operating at higher frequencies.

The advancement, recently published in the journal Nature, stems from collaborative research involving scientists from the University of Colorado Boulder, the University of Arizona, and Sandia National Laboratories. At its core, the innovation leverages surface acoustic waves (SAWs) within a device engineered to function as a laser for sound-like vibrations rather than light. This represents a critical step towards consolidating complex radio frequency (RF) functionalities onto a single, highly integrated semiconductor platform, a long-sought goal in the electronics industry.

Understanding Surface Acoustic Waves: The Foundation of Modern Wireless

Surface acoustic waves are a class of mechanical waves that propagate along the surface of a material, distinct from bulk sound waves that travel through its interior. While large-scale SAWs are responsible for the destructive shaking during earthquakes, their microscopic counterparts are already indispensable to contemporary technology. These waves are critical components in virtually every modern smartphone, remote key fob, GPS receiver, and advanced radar system.

In their current application, SAWs serve primarily as highly efficient filters within RF circuits. When a radio signal, such as one from a cellular tower, reaches a smartphone, it is first converted into minute mechanical vibrations. This mechanical representation allows for precise filtering, separating the desired signal from a spectrum of interference and background noise. Once processed, these "cleaned" vibrations are converted back into electrical signals for digital processing. This electromechanical conversion, facilitated by SAW devices, provides superior performance in terms of signal selectivity and power efficiency compared to purely electronic filters. The inherent properties of SAWs allow for the creation of compact, high-performance filters that are essential for handling the myriad frequencies used in modern wireless communication.

However, existing SAW-based systems typically involve multiple discrete components and often require external power sources, limiting their integration density and overall efficiency. These traditional architectures also face practical limits on the operational frequencies they can achieve, typically topping out around 4 gigahertz (GHz) for mass-produced devices. Overcoming these limitations has been a significant challenge for engineers striving to meet the escalating demands for bandwidth, speed, and miniaturization in next-generation wireless standards like 5G and future 6G networks.

The Emergence of the Phonon Laser: A Paradigm Shift

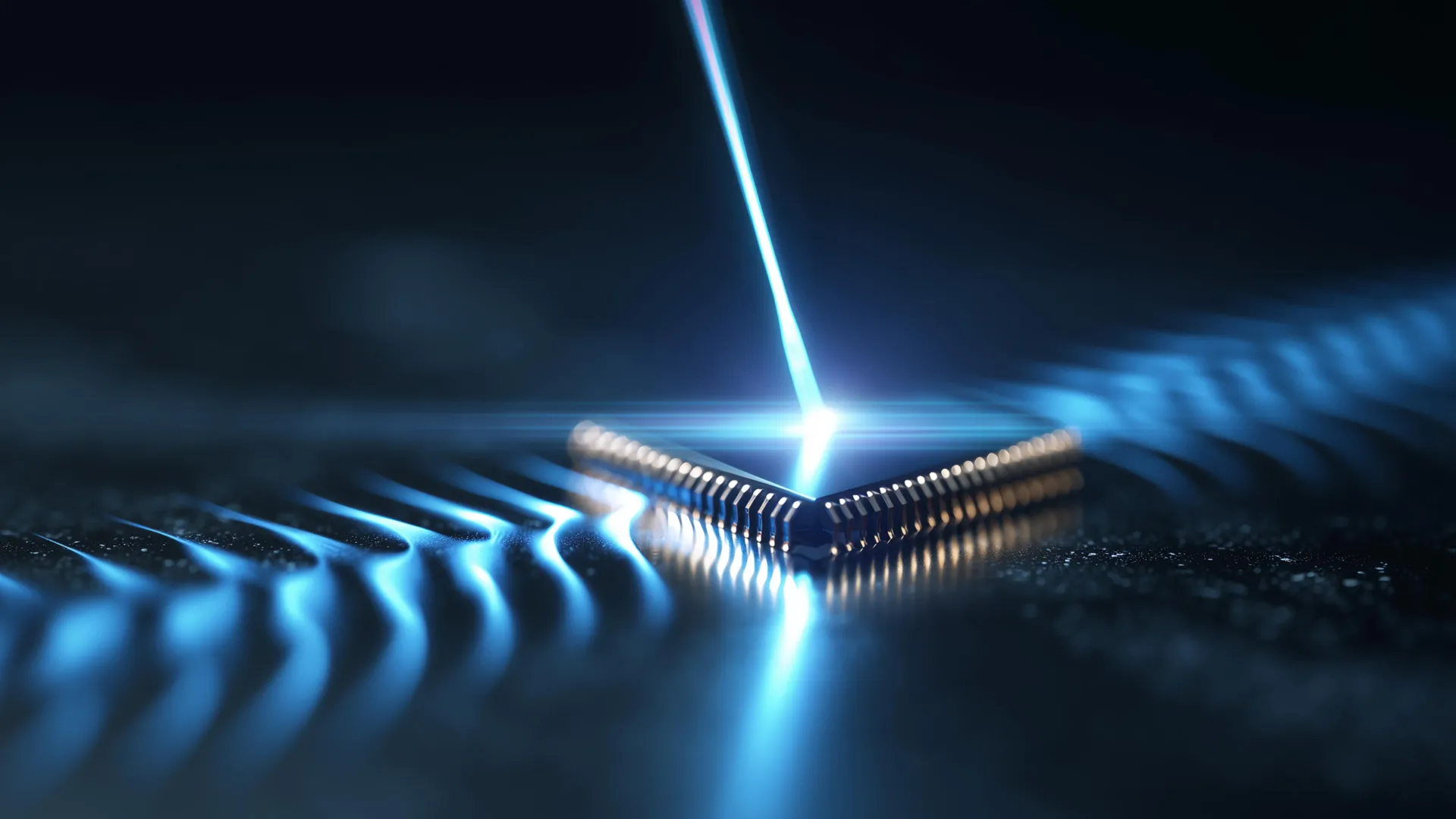

The breakthrough lies in the creation of a "phonon laser," a device that generates controlled surface acoustic waves through a mechanism analogous to how conventional diode lasers produce light. Unlike an optical laser that amplifies photons (light particles), this device amplifies phonons (quantized units of vibrational energy). The research team’s innovation focuses on creating an active gain medium for mechanical vibrations, allowing for the coherent generation and amplification of SAWs within a single, integrated chip.

To grasp the novelty of this phonon laser, it is helpful to consider the operational principles of a standard diode laser. Diode lasers generate light by bouncing it between two tiny mirrors within a semiconductor cavity. As light traverses this cavity, it interacts with atoms energized by an electric current. These energized atoms release additional photons, a process known as stimulated emission, which strengthens the light beam with each pass. The mirrors ensure a feedback loop, allowing the light to build up until a portion escapes as a coherent laser beam.

The phonon laser replicates this fundamental concept for mechanical vibrations. The device, approximately half a millimeter in length, features a layered architecture designed to create an analogous feedback and amplification loop for SAWs. The base layer is silicon, providing a robust and industry-standard substrate. Above this lies a thin layer of lithium niobate, a material renowned for its piezoelectric properties. Piezoelectric materials exhibit a unique characteristic: they generate an electric field when subjected to mechanical stress, and conversely, they vibrate when exposed to an electric field. This bidirectional coupling is crucial for the electromechanical conversion fundamental to SAW devices. The uppermost layer consists of an extremely thin sheet of indium gallium arsenide, a semiconductor known for its unusual electronic properties, particularly its ability to accelerate electrons to very high velocities even under weak electric fields.

Mechanism of Operation: Engineering Vibrational Gain

The ingenious design allows vibrations propagating along the lithium niobate surface to interact directly and efficiently with the high-speed electrons within the indium gallium arsenide layer. When an electric current is applied to the indium gallium arsenide, it energizes these electrons. As surface acoustic waves travel through the lithium niobate, they induce oscillating electric fields. These fields, in turn, interact with the fast-moving electrons in the indium gallium arsenide, causing the electrons to transfer energy to the passing SAWs. This energy transfer acts as a gain mechanism, actively amplifying the mechanical vibrations.

The device incorporates reflective elements at its ends, effectively creating a resonant cavity for the SAWs, much like the mirrors in an optical laser. As waves travel forward, they gain energy from the electron interaction. Upon striking a reflector, they bounce back, traversing the gain medium again. While some energy loss inevitably occurs during this propagation, particularly on the backward pass, the forward gain is engineered to be substantial enough to overcome these losses. This iterative process leads to a significant amplification of the SAWs. After multiple passes, the vibrations accumulate sufficient energy and coherence, causing a portion of them to "leak out" from one side of the device, forming a highly controlled, high-frequency phonon beam. This controlled emission of amplified surface acoustic waves is the essence of the phonon laser.

Performance and Future Trajectories

The experimental results demonstrated the generation of surface acoustic waves at approximately 1 GHz, representing billions of oscillations per second. Crucially, the researchers project that this foundational design can be scaled to achieve frequencies in the tens or even hundreds of gigahertz. This capability far surpasses the practical limits of traditional SAW devices, which typically plateau around 4 GHz, making the new system potentially orders of magnitude faster.

The implications of this enhanced speed and miniaturization are profound. Current smartphones and other wireless devices rely on a complex chain of conversions: radio waves to SAWs, processing, and then SAWs back to radio waves, often requiring multiple chips and conversions for different frequency bands. The phonon laser offers the tantalizing prospect of integrating all necessary RF signal processing components onto a single, compact chip. This would drastically reduce the physical footprint of RF front-ends, decrease power consumption, and enable higher data throughput.

For the consumer electronics sector, this translates directly into thinner, lighter, and more powerful smartphones with extended battery life. For the broader wireless ecosystem, it paves the way for more sophisticated and efficient Internet of Things (IoT) devices, advanced 5G and future 6G communication infrastructure, and next-generation radar systems with enhanced resolution and detection capabilities. The ability to generate and manipulate coherent phonons at such high frequencies could also open doors to novel applications in quantum computing interfaces, where mechanical vibrations could serve as carriers of quantum information, or in highly sensitive sensor technologies.

This breakthrough represents not merely an incremental improvement but a fundamental shift in how engineers can manipulate mechanical energy at the nanoscale. By establishing a robust method for creating a compact, battery-operable phonon laser, the research team has effectively completed a critical piece of the puzzle for fully integrated, high-performance acoustic-electronic systems. The vision of a single chip handling all radio frequency operations using this advanced acoustic technology is now significantly closer to becoming a reality, heralding a new era of ultra-compact and efficient wireless communication.