The relentless global surge in electricity consumption, driven by the proliferation of energy-intensive data centers supporting advanced artificial intelligence, coupled with expanding industrial manufacturing sectors, exerts unprecedented strain on power infrastructure worldwide. Addressing this escalating demand necessitates a multifaceted strategy that extends beyond merely increasing generation capacity; it critically requires a fundamental shift towards optimizing the efficiency and cost-effectiveness of existing energy supplies.

Redefining Power Conversion Efficiency

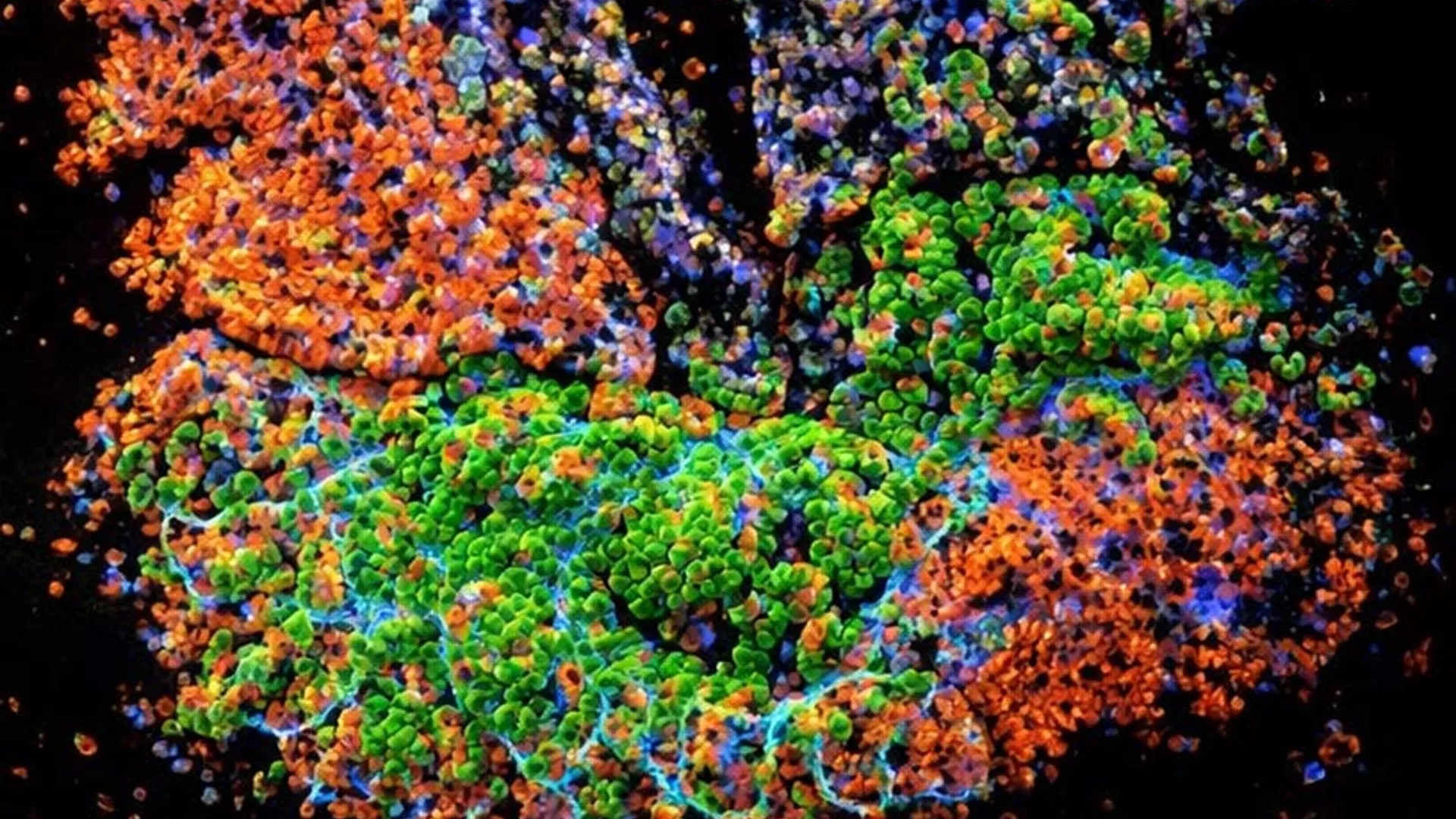

A groundbreaking innovation emerges from the National Renewable Energy Laboratory (NREL), where researchers have engineered a novel silicon carbide-based power module poised to significantly enhance the conversion and delivery of electrical power. This development centers on the "power module," which serves as the protective enclosure for power electronics—components essential for regulating electricity flow between diverse systems. The new design sets benchmarks for efficiency, achieves remarkable power density, and incorporates a manufacturing methodology designed to minimize production costs.

Designated NREL’s Ultra-Low Inductance Smart power module, or ULIS, this technology leverages advanced silicon carbide semiconductors to attain an energy density five times greater than previous designs, all within a substantially reduced physical footprint. This synergistic combination empowers manufacturers to develop equipment that is notably smaller, lighter, and more energy-efficient. The module, rated at 1200 volts and 400 amperes, demonstrates broad applicability across critical infrastructure domains, including expansive data centers, national electrical grids, compact microreactors, and high-performance platforms such as next-generation aviation systems and sophisticated military vehicles.

The Critical Imperative of Ultra-Low Inductance

A foundational advantage inherent to ULIS is its extraordinarily low parasitic inductance. This phenomenon, parasitic inductance, refers to an intrinsic resistance within an electrical circuit that impedes rapid changes in current flow, thereby diminishing the efficiency of power conversion. ULIS meticulously engineers this resistance down to an unprecedented level, reducing it by a factor of seven to nine compared to even the most advanced silicon carbide power modules currently available.

The capacity of ULIS to modulate electrical current with extreme rapidity and precision directly translates into superior energy conversion. This means a larger proportion of the input electricity is transformed into usable power, minimizing dissipative losses. This enhanced capability allows ULIS to extract substantially greater value from a given energy supply, positioning it as a pivotal technology for addressing the accelerating global energy requirements and fostering sustainable growth.

Faisal Khan, NREL’s chief power electronics researcher and the principal investigator for this transformative project, characterizes ULIS as a "true breakthrough." He emphasizes its role as a "future-proofed, ultrafast power module" poised to render subsequent generations of power converters more economically viable, operationally efficient, and physically compact. This assessment underscores the profound potential of ULIS to influence the trajectory of power electronics development for years to come.

Engineered for Unwavering Reliability in Demanding Environments

Beyond its paramount efficiency, ULIS has been meticulously engineered for exceptional reliability, particularly within environments characterized by extreme operational demands. According to Khan, the module, despite its lightweight and powerful characteristics, integrates sophisticated self-monitoring capabilities. This allows it to continuously assess its own operational status and proactively identify potential component failures before they manifest, thereby mitigating the risk of unexpected outages.

This predictive maintenance feature holds immense strategic importance for high-stakes applications, notably in the fields of aviation and military operations. For aircraft operating at altitudes of 30,000 feet or ground vehicles navigating hazardous combat zones, the timely detection and prediction of component degradation can represent the decisive factor between the successful execution of a mission and a catastrophic system failure or loss of life. The internal development of ULIS, conducted entirely within NREL, further highlights the integrated expertise and comprehensive approach applied to its design and validation, with Khan expressing considerable enthusiasm for its impending real-world performance demonstrations.

A Radical Redesign Driving Cost-Effective Manufacturing

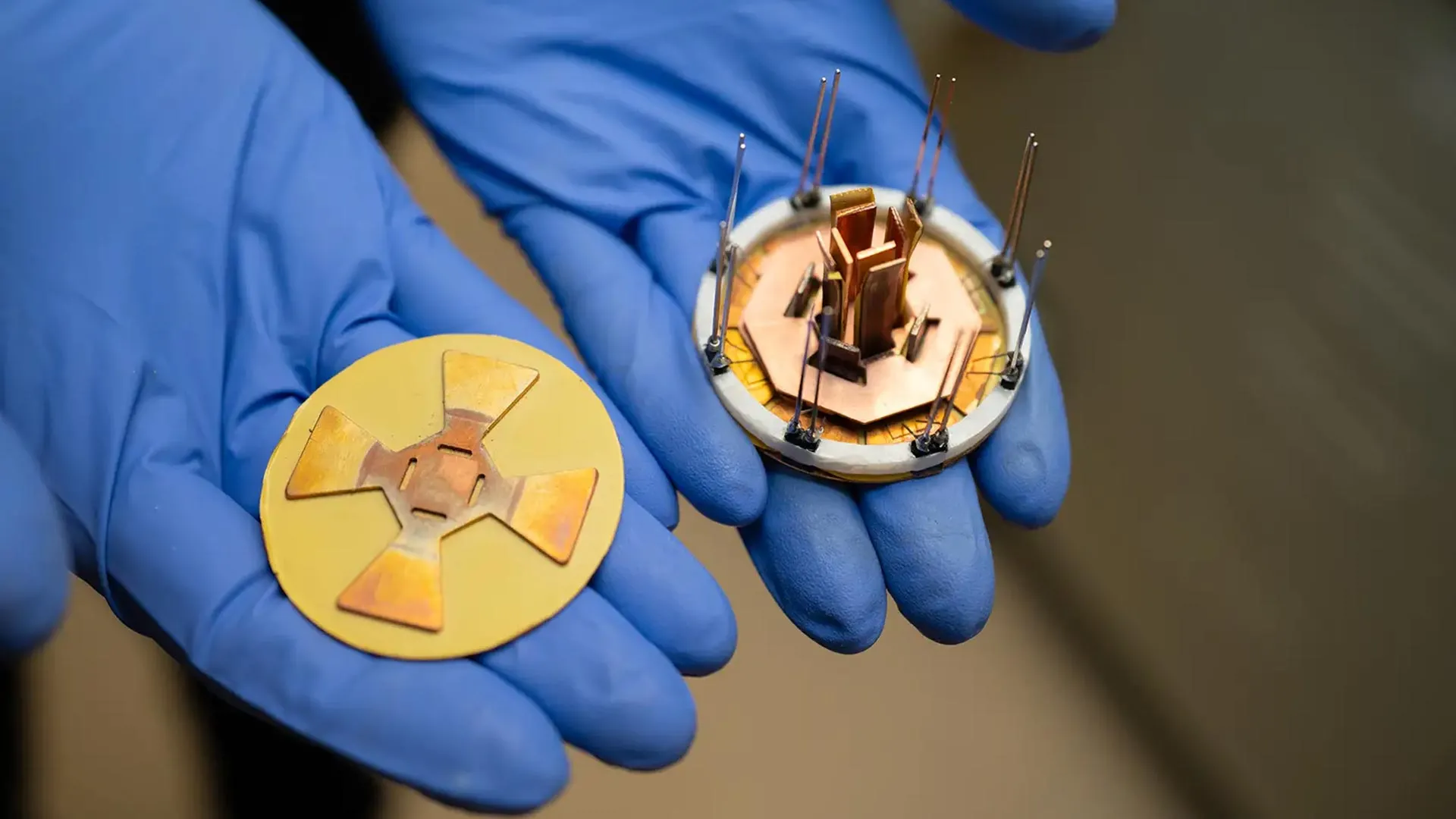

A significant proportion of ULIS’s performance advancements are attributable to a completely re-imagined physical architecture. Conventional power modules typically arrange semiconductor devices in vertically stacked configurations within box-like enclosures. In stark contrast, ULIS employs a flat, octagonal layout for its circuitry. This innovative disk-shaped structure facilitates the integration of a greater number of components within a reduced footprint, contributing to both a smaller overall size and lighter weight. Concurrently, its pioneering current routing methodology minimizes magnetic interference, which is crucial for delivering a cleaner electrical output and achieving superior overall efficiency.

Shuofeng Zhao, an NREL power electronics researcher who played a pivotal role in conceiving ULIS’s flux cancellation architecture, elaborated on a primary design consideration: ensuring the device’s ability to switch electrical current on and off with extreme rapidity without creating internal "chokepoints" that would impede performance. Initial conceptualizations explored intricate three-dimensional geometries, including designs reminiscent of botanical forms or hollow cylinders. However, these complex approaches were ultimately deemed impractical due to their prohibitive manufacturing costs and inherent production difficulties.

The pivotal breakthrough occurred when the research team radically simplified the concept into an almost two-dimensional structure. Sarwar Islam, another NREL power electronics researcher, was instrumental in proposing this flattened design, which successfully balanced the competing demands of performance, cost-effectiveness, and manufacturability. Zhao vividly described this transformative simplification: "We squished it flat, like a pancake," a design choice that unexpectedly yielded a low-cost, high-performing module significantly easier to fabricate. Joshua Major, also a member of the NREL power electronics team, further refined these fabrication processes, enabling the production of this intricate structure using exclusively in-house tools and facilities. The culmination of these efforts was a design that masterfully combined the electrical benefits traditionally associated with three-dimensional systems with the practical advantages of flat manufacturing techniques.

Flexible Materials and Integrated Wireless Control

ULIS also deviates significantly from conventional material selections in power module construction. Historically, traditional power modules relied on directly bonding copper conductors to rigid ceramic bases, a method effective for electrical conduction and thermal management but inherently limiting in terms of mechanical flexibility.

Instead, ULIS innovatively bonds copper to Temprion, a flexible polymer substrate. This material shift results in a module that is thinner, lighter, and considerably more adaptable. The bonding process for Temprion with copper requires only heat and pressure, and its components can be precisely machined using widely accessible industrial equipment. Consequently, the manufacturing costs for ULIS modules are dramatically reduced, falling into the hundreds of dollars rather than the thousands, making the technology far more scalable and accessible.

A further significant advancement is ULIS’s capacity for wireless operation. The module can be controlled and monitored without the need for physical cables, functioning as an entirely self-contained unit. This inherent modularity, akin to interlocking building blocks, facilitates its seamless integration into a vast array of systems, ranging from enterprise data center servers to sophisticated next-generation aircraft and advanced military vehicles. A patent application for the underlying low-latency wireless communication protocol, spearheaded by Sarwar Islam, is currently under review, underscoring the innovative nature of this connectivity solution.

Architectural Foresight: Designed for Future Technologies

While ULIS presently harnesses the capabilities of advanced silicon carbide semiconductors, its design philosophy deliberately incorporates an evolutionary pathway. The module’s architecture is intentionally adaptable, allowing for future integration with emergent semiconductor materials. This includes promising technologies such as gallium nitride (GaN) and gallium oxide (Ga2O3), the latter of which has yet to achieve widespread commercial deployment. This forward-looking design ensures that ULIS can remain at the forefront of power electronics innovation as material science progresses.

Collectively, these myriad innovations converge on a singular, overarching objective: to deliver unparalleled efficiency without compromising dependability, particularly as global societies become increasingly reliant on uninterrupted and reliable electricity supplies. ULIS represents a strategic advancement in meeting this critical societal need.

Transformative Impact Across Key Sectors

The strategic deployment of ULIS is anticipated to yield far-reaching impacts across a multitude of critical sectors.

Within the United States’ national power grid, electricity undergoes numerous conversion processes before it is distributed to end-users. These conversions often rely on substantial, low-frequency equipment that inherently sacrifices efficiency. ULIS’s rapid switching capabilities dramatically improve this efficiency, while its robust tolerance for elevated operating temperatures promises to reduce long-term maintenance expenditures, thereby enhancing grid stability and economic viability.

In the aviation industry, the module’s ability to swiftly transfer electricity and conserve energy translates directly into lighter and more potent power converters. This technological leap could be instrumental in making electric vertical takeoff and landing (eVTOL) aircraft not only technically feasible but also commercially viable and scalable for urban air mobility and other applications.

Furthermore, ULIS is positioned to play a crucial role in the development of future fusion energy systems. While commercial fusion power remains in its developmental stages, such systems will necessitate exceptionally compact and reliable pulsed power components capable of handling immense energy discharges. ULIS’s ultra-low inductance and robust, durable design make it an exceptionally well-suited candidate for addressing the unique and demanding challenges inherent to fusion energy research and eventual commercialization.

As industries globally continue to pursue increasingly reliable electricity sources, sophisticated artificial intelligence infrastructure, and the next generation of advanced vehicles, ULIS represents a timely and critical technological offering. The module is now available for licensing, signaling its readiness for broad industrial adoption and integration into the energy ecosystems of tomorrow.