A groundbreaking innovation in material science promises to fundamentally alter the environmental footprint of the global construction sector, introducing a novel structural compound that actively sequesters atmospheric carbon dioxide during its creation and lifespan.

The pervasive challenge of decarbonizing the built environment has long presented a formidable obstacle in the global pursuit of climate stability. The production of traditional building materials, particularly concrete, stands as a significant contributor to greenhouse gas emissions, demanding substantial energy inputs and releasing vast quantities of carbon dioxide into the atmosphere. However, a recent breakthrough by researchers at Worcester Polytechnic Institute (WPI) offers a compelling solution: an enzymatic structural material (ESM) engineered not only to significantly reduce embodied carbon but to achieve a net carbon-negative status. This advanced composite, detailed in the prestigious journal Matter, leverages biological processes to transform carbon dioxide into a durable, recyclable, and energy-efficient construction component, signaling a potential paradigm shift for sustainable infrastructure development worldwide.

The Carbon Conundrum in Construction

To fully appreciate the significance of ESM, it is crucial to understand the scale of the environmental impact associated with conventional construction practices. Concrete, the most ubiquitous man-made material on Earth, is responsible for approximately 8% of global anthropogenic CO2 emissions. This staggering figure primarily stems from the production of Portland cement, its key binder. The manufacturing process of cement involves heating limestone and other minerals to extremely high temperatures—upwards of 1,450 degrees Celsius—in massive kilns. This pyrotechnic process, known as calcination, chemically liberates CO2 from the limestone. Concurrently, the combustion of fossil fuels required to achieve and maintain these intense temperatures further exacerbates the carbon footprint. Beyond emissions, concrete production consumes vast amounts of water and aggregates, contributing to resource depletion and ecological disturbance.

Current efforts to mitigate concrete’s environmental impact include optimizing mix designs, incorporating supplementary cementitious materials (SCMs) like fly ash or slag, and exploring carbon capture technologies at cement plants. While these strategies offer incremental improvements, they largely focus on reducing emissions rather than actively removing CO2 from the atmosphere. The pursuit of truly carbon-negative materials has remained an ambitious frontier, until now. The introduction of ESM represents a substantial leap forward, moving beyond mere emission reduction to active atmospheric carbon sequestration, thereby addressing both the embodied carbon and the climate crisis simultaneously.

Enzymatic Structural Material: A Deep Dive into Its Biomineralization Core

At the heart of the ESM innovation lies a sophisticated biomineralization process, inspired by natural biological systems. The research team, spearheaded by Professor Nima Rahbar, the Ralph H. White Family Distinguished Professor and head of the Department of Civil, Environmental, and Architectural Engineering at WPI, harnessed a specific enzyme to catalyze the conversion of gaseous carbon dioxide into solid mineral particles. This enzymatic action mimics natural processes where organisms like corals and mollusks form robust calcium carbonate structures from dissolved CO2. In the context of ESM, this enzyme facilitates the rapid precipitation of carbonate minerals, effectively locking atmospheric carbon into a stable, solid form.

The precise mechanism involves the enzyme accelerating the hydration of CO2 to carbonic acid, which then dissociates, leading to an increase in local pH and subsequent precipitation of carbonate ions with available metal cations (e.g., calcium ions) to form solid mineral phases. These nascent mineral particles serve as the fundamental building blocks of ESM. Unlike the energy-intensive clinkering process of cement, this biomineralization occurs under ambient, "gentle conditions," dramatically reducing the energy expenditure typically associated with material synthesis. The mineral particles are then carefully bonded together and cured, enabling the formation of structural components within a matter of hours. This rapid fabrication contrasts sharply with conventional concrete, which can take weeks to achieve full strength, demanding extended site times and associated costs. The energy savings inherent in ESM’s production not only lower its overall environmental impact but also hold significant implications for its economic viability and scalability.

Unprecedented Performance and Environmental Footprint

The performance metrics of ESM underscore its transformative potential. A single cubic meter of this innovative material sequesters more than 6 kilograms of CO2 from the atmosphere. This stands in stark contrast to conventional concrete, which emits approximately 330 kilograms of CO2 for every cubic meter produced. This difference represents an unparalleled shift from a high-emission material to one that actively contributes to carbon removal, offering a powerful tool in the fight against climate change. The sequestered carbon is chemically integrated into the material’s structure, ensuring its long-term stability and permanence, effectively turning building elements into carbon sinks.

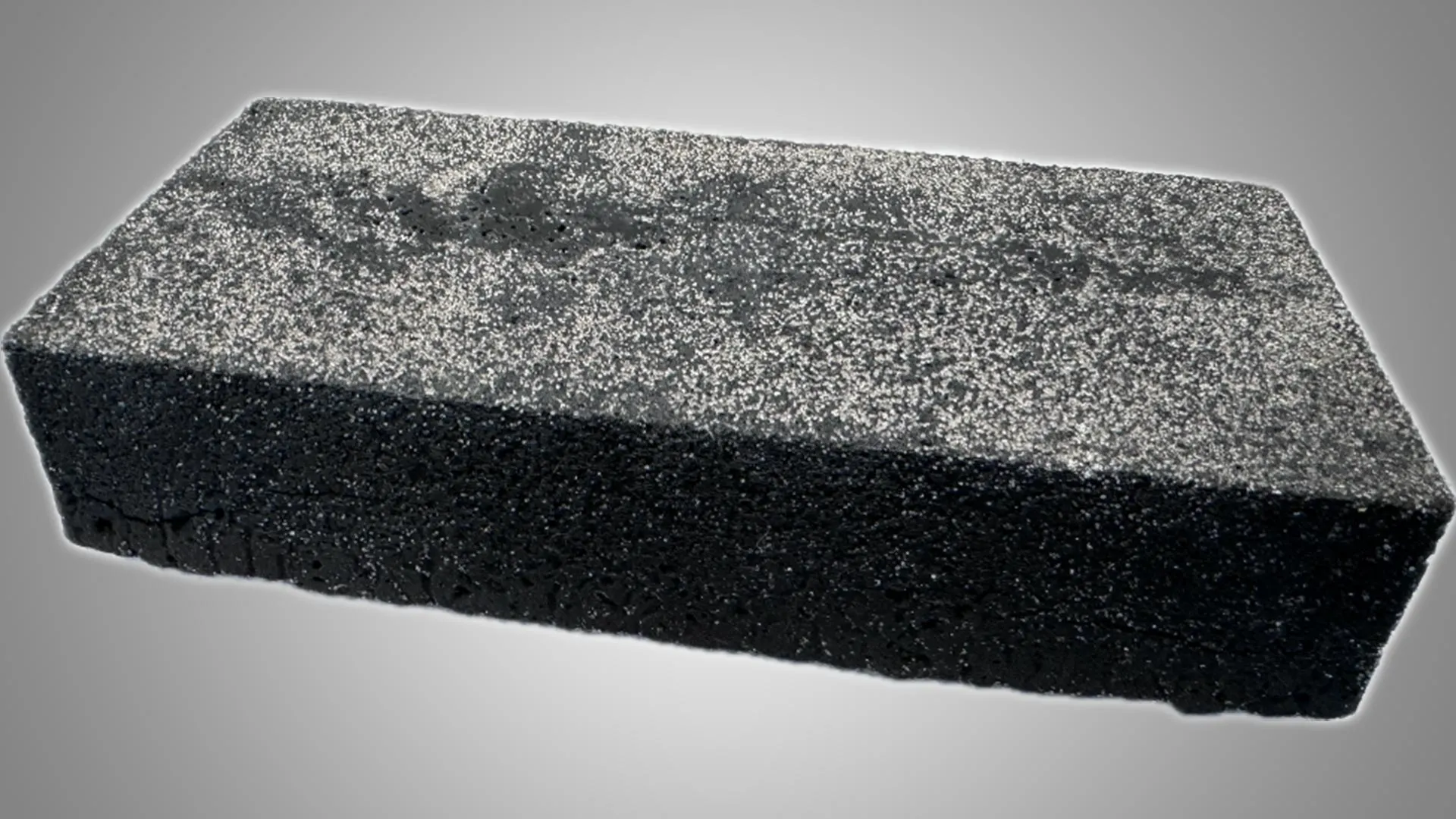

Beyond its carbon-negative status, ESM exhibits a suite of properties tailored for practical construction applications. It offers adjustable strength characteristics, allowing for customization based on specific structural requirements, from lightweight panels to more robust load-bearing elements. Its rapid curing capabilities significantly accelerate construction timelines, a critical advantage for projects with tight schedules or in rapid deployment scenarios. Furthermore, ESM is designed for full recyclability, supporting the principles of a circular economy by minimizing waste and enabling the reuse of materials at the end of a structure’s life. The material’s repairability further enhances its sustainability profile, reducing long-term maintenance costs and extending the service life of infrastructure, thereby diminishing the need for new material production and landfill contributions.

Broadening the Horizons of Application and Societal Impact

The versatility of ESM positions it for a wide array of applications across the construction spectrum. Its suitability for elements such as roof decks, wall panels, and modular building systems highlights its potential to streamline construction processes and reduce material weight. The inherent advantages of rapid fabrication and reduced energy consumption make ESM particularly attractive for initiatives focused on affordable housing, where cost-effectiveness and speed of construction are paramount. By enabling quicker assembly and potentially lower material costs over its lifecycle, ESM could play a pivotal role in addressing housing shortages and improving living conditions globally.

Furthermore, the material’s properties lend themselves to the development of climate-resilient infrastructure. Its durability, combined with the ability to be rapidly deployed and repaired, makes it an ideal candidate for regions susceptible to extreme weather events. In disaster recovery efforts, where swift and efficient rebuilding is crucial, lightweight ESM components could significantly accelerate the reconstruction of homes and essential services, minimizing the prolonged displacement and economic hardship faced by affected communities. The integration of ESM into infrastructure projects could bolster resilience against environmental degradation and climate-induced stressors, creating a built environment that is both sustainable and robust.

Navigating the Path to Widespread Adoption: Challenges and Future Outlook

While the scientific and environmental promise of ESM is immense, its journey from laboratory breakthrough to widespread industrial adoption will undoubtedly involve navigating several critical challenges. Scaling up production to meet the demands of the global construction market requires significant investment in manufacturing infrastructure, optimizing the enzyme production, and securing reliable, sustainable sources for the necessary chemical inputs. Establishing consistent quality control and standardization for a novel material will also be essential to ensure its performance meets stringent building codes and regulatory requirements worldwide. The construction industry, often characterized by its conservative nature and reliance on established practices, may require extensive education and demonstration projects to fully embrace such a disruptive innovation. Architects, engineers, and developers will need to be trained in its properties and application methods.

Looking ahead, continued research will focus on further optimizing the enzymatic process, exploring the use of diverse and abundant raw materials, and validating the long-term performance and durability of ESM in various environmental conditions. Economic viability will be a crucial factor in its market penetration, requiring competitive pricing compared to conventional materials, especially as production scales. Policy frameworks that incentivize carbon-negative materials and circular economy principles will also be instrumental in accelerating ESM’s integration into mainstream construction.

The vision articulated by Professor Rahbar—that "if even a fraction of global construction shifts toward carbon-negative materials like ESM, the impact could be enormous"—underscores the profound potential of this innovation. ESM represents more than just a new building material; it embodies a paradigm shift towards a carbon-negative, resource-efficient, and truly sustainable built environment. By transforming our buildings from carbon emitters into carbon sinks, ESM offers a tangible pathway to addressing one of the most pressing environmental challenges of our time, laying the foundation for a greener, more resilient future.