For generations, the global food industry and scientific community have pursued the elusive goal of replicating sugar’s universally appealing taste and functional properties without its detrimental health consequences. This persistent quest, driven by the escalating worldwide burden of metabolic diseases and dental issues, has seen the development of numerous artificial sweeteners and sugar alcohols, each presenting its own set of advantages and limitations. Now, a significant advance in metabolic engineering points towards a promising future, offering a naturally occurring sugar that delivers the desired sweetness with substantially reduced caloric impact and potential therapeutic benefits.

The persistent challenge in the realm of food science has been to discover or synthesize a compound that perfectly mimics the sensory experience of sucrose – table sugar – while circumventing the metabolic pitfalls associated with its high consumption. Sucrose, a disaccharide composed of glucose and fructose, is a primary driver of excess calorie intake, contributing directly to the global epidemics of obesity, insulin resistance, type 2 diabetes, and dental caries. Early attempts to replace sugar, dating back to the late 19th century with saccharin, and continuing through the 20th century with cyclamates, aspartame, and sucralose, have met with varying degrees of consumer acceptance, often hampered by issues such as metallic aftertastes, perceived safety concerns, or an inability to replicate sugar’s crucial textural and browning properties in culinary applications. More recent natural alternatives like stevia and monk fruit extracts provide high intensity sweetness but lack the "bulk" and functional characteristics essential for baking and other food formulations, leading to a continuous demand for a truly comprehensive sugar substitute.

This critical gap in the market and in public health strategies may now be addressed by a novel biotechnological approach to produce tagatose. A recent study, detailed in a prominent scientific journal, outlines a groundbreaking biosynthetic method developed by researchers at a leading academic institution. This innovation focuses on significantly improving the yield and cost-effectiveness of producing tagatose, a naturally occurring monosaccharide that closely replicates the taste profile of sucrose. Beyond its appealing flavor, tagatose offers a dramatically lower caloric content and a distinctive metabolic pathway that positions it as a potentially revolutionary ingredient in the ongoing battle against sugar-related diseases. The researchers involved in this work suggest that tagatose could not only mitigate the negative impacts of traditional sugar but also confer additional health advantages, thereby redefining the landscape of healthful sweeteners.

Unpacking Tagatose: A Rare Monosaccharide with Unique Properties

Tagatose is a ketohexose, an isomer of fructose, meaning it shares the same chemical formula but has a different structural arrangement. While it exists in nature, its presence is remarkably scarce. Trace amounts are found in dairy products, particularly those undergoing fermentation or heat treatment, such as yogurt, cheese, and kefir, where it is formed through the enzymatic breakdown of lactose. Similarly, minuscule quantities have been detected in certain fruits like apples, pineapples, and oranges. However, the concentration of tagatose in these natural sources is typically less than 0.2% of the total sugar content, rendering direct extraction impractical and economically unviable for industrial scale production. This inherent scarcity has historically necessitated its synthesis through more complex and costly manufacturing processes, primarily involving the enzymatic conversion of galactose, a monosaccharide derived from lactose.

The limited natural abundance of tagatose has been a significant barrier to its widespread adoption, despite its recognized potential as a healthier sweetener. Traditional industrial production methods, while functional, have been characterized by their inefficiency, high production costs, and often, the requirement for specific, relatively expensive starting materials like galactose. These factors have historically confined tagatose to niche applications, preventing it from competing effectively with more readily available and cheaper conventional sugars or artificial sweeteners. The economic viability of any sugar alternative hinges on its ability to be produced at a scale and cost that allows for broad integration into the food supply chain.

Metabolic Engineering: Transforming Bacteria into Biorefineries

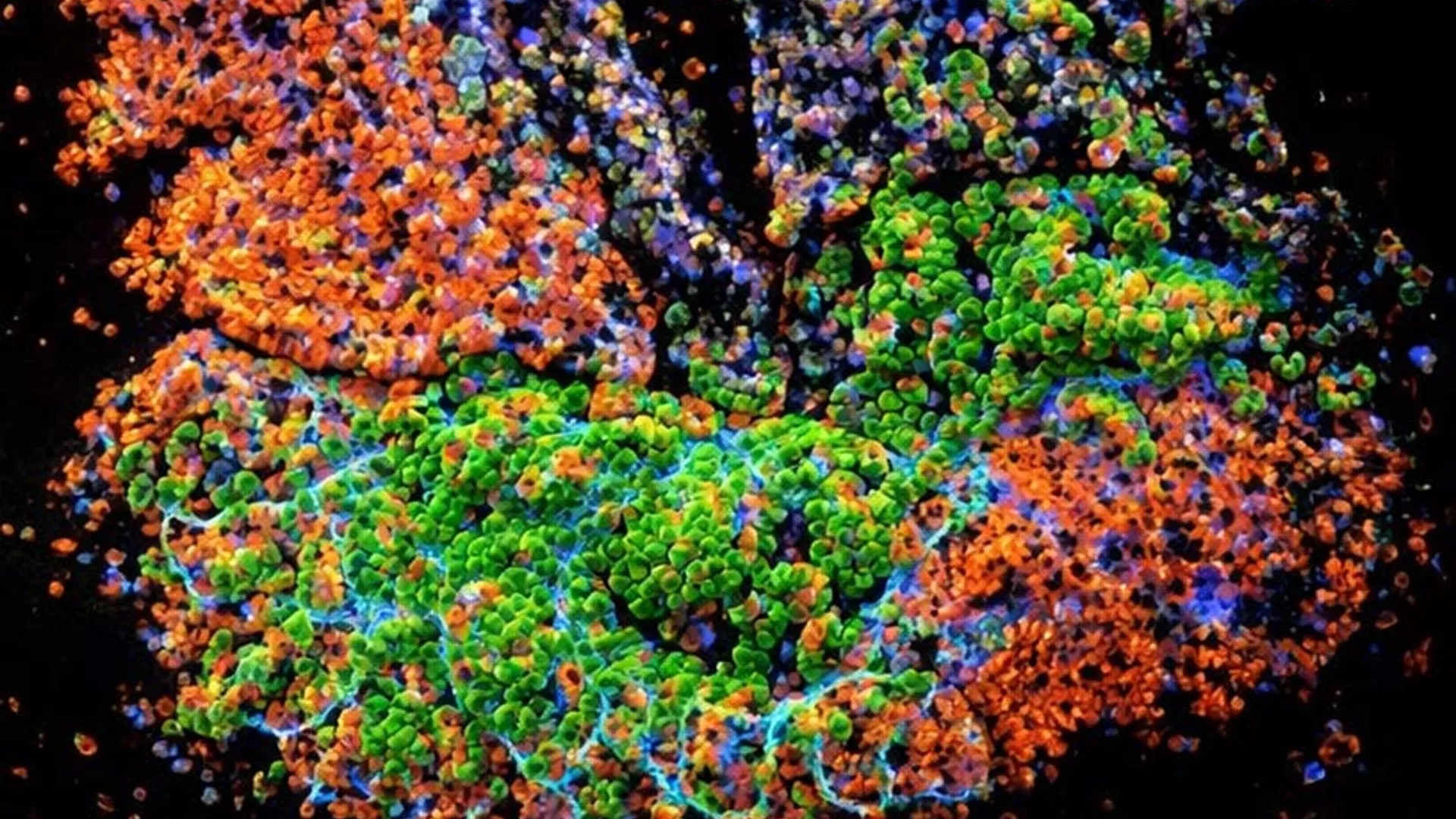

The breakthrough outlined by the research team lies in a sophisticated application of metabolic engineering, a field that uses genetic tools to reprogram cellular machinery for the efficient production of desired compounds. Recognizing the limitations of existing tagatose synthesis routes, the scientists devised a novel strategy centered on genetically modifying Escherichia coli bacteria. These ubiquitous microorganisms were transformed into highly efficient "microbial factories," specifically engineered to convert abundant and inexpensive glucose into high-purity tagatose.

The core innovation involved the strategic introduction of a previously uncharacterized enzyme, galactose-1-phosphate-selective phosphatase (Gal1P), sourced from slime mold. This enzyme plays a pivotal role by enabling the engineered E. coli to generate galactose directly from glucose. This is a crucial step, as it circumvents the need for external galactose supply, which is often more expensive and less abundant than glucose. Following the successful conversion of glucose to galactose, another enzyme naturally produced by the bacteria, arabinose isomerase, then facilitates the final transformation of galactose into tagatose. This two-step enzymatic cascade within the engineered bacterial system represents a significant advance in biotechnological synthesis.

The efficiency metrics of this new biosynthetic pathway are particularly impressive. The engineered E. coli strains demonstrated the ability to convert glucose into tagatose with yields as high as 95%. This figure represents a substantial improvement over traditional manufacturing techniques, which typically achieve yields ranging from 40% to 77%. The implications of such high conversion efficiency are profound. Higher yields directly translate to lower production costs, reduced raw material consumption, and a more sustainable manufacturing process. This enhanced economic feasibility is critical for positioning tagatose as a viable, large-scale sugar alternative in a highly competitive global market. Furthermore, utilizing glucose as the primary feedstock, a globally abundant and renewable resource, reinforces the sustainability and scalability of this innovative production method.

A Multifaceted Profile: Sweetness, Safety, and Health Benefits

Tagatose’s appeal extends far beyond its improved production economics; its intrinsic properties offer a compelling profile as a healthier sweetener. It delivers approximately 92% of the sweetness intensity of sucrose, providing a familiar and satisfying taste without the off-notes or lingering aftertastes often associated with high-intensity artificial sweeteners. Critically, it contains roughly 60% fewer calories than sucrose, significantly reducing the caloric load in food and beverage products.

The safety of tagatose for human consumption has been rigorously assessed, leading to its classification by the U.S. Food and Drug Administration (FDA) as "generally recognized as safe" (GRAS). This designation signifies that, based on extensive scientific evidence and expert consensus, tagatose is considered safe for use in food products, similar to common ingredients like salt, vinegar, and baking soda. The GRAS status is a crucial regulatory milestone, paving the way for its broad integration into consumer goods.

One of the most significant health advantages of tagatose relates to its unique metabolic fate, particularly beneficial for individuals managing diabetes or seeking to maintain stable blood glucose levels. Unlike conventional sugars, which are rapidly and fully absorbed in the small intestine, only a fraction of ingested tagatose is absorbed there. A substantial portion of tagatose passes undigested into the colon, where it is fermented by gut bacteria. This partial absorption mechanism results in a significantly lower glycemic index and a minimal impact on blood glucose and insulin levels compared to sucrose. Clinical studies have consistently demonstrated only negligible increases in plasma glucose or insulin concentrations following tagatose consumption, making it an attractive option for glycemic control.

Beyond its favorable glycemic profile, tagatose also offers potential benefits for oral health. Sucrose is a primary substrate for cariogenic bacteria, such as Streptococcus mutans, which metabolize it to produce acids that erode tooth enamel, leading to cavities. In contrast, research suggests that tagatose not only limits the growth of these harmful microbes but may also actively promote a healthier oral microbiome. Its unique structure prevents efficient metabolism by these detrimental bacteria, thereby reducing acid production and subsequent demineralization of tooth structure.

Furthermore, the unabsorbed portion of tagatose that reaches the colon acts as a prebiotic, fostering the growth of beneficial gut bacteria. This prebiotic effect can contribute to a healthier gut microbiome, which is increasingly recognized for its widespread influence on overall health, including immune function, nutrient absorption, and even mood regulation. By supporting a balanced gut flora, tagatose could offer systemic health benefits beyond simple caloric reduction and glycemic control.

Culinary Versatility: A Sugar That Performs Like Sugar

A key limitation of many sugar alternatives has been their inability to replicate the functional properties of sucrose in cooking and baking. High-intensity sweeteners provide sweetness but lack the "bulk," texture, browning capabilities, and mouthfeel that sugar imparts. This functional gap often necessitates the use of bulking agents or compromises in product quality. Tagatose, however, shines as a "bulk sweetener" due to its physical and chemical properties.

Its crystalline structure and solubility allow it to contribute to the desired texture and volume in baked goods, confections, and beverages. Crucially, tagatose participates in the Maillard reaction, the complex chemical process responsible for the desirable browning and flavor development in many cooked foods. This attribute is vital for products like cookies, cakes, and certain sauces, where the caramelization and rich flavor notes derived from sugar are essential. Taste tests have consistently indicated that tagatose closely matches the flavor, sweetness profile, and mouthfeel of conventional sugar, without introducing undesirable off-flavors or sensations. This comprehensive functional performance positions tagatose as an ideal ingredient for food manufacturers seeking to reduce sugar content without sacrificing sensory appeal or product integrity.

Broader Implications and The Future of Sweeteners

The innovation in tagatose biosynthesis represents more than just an improved method for producing a single sugar; it signifies a paradigm shift in the approach to rare sugar production. The researchers highlight that the identification and strategic integration of enzymes like slime mold Gal1P into bacterial hosts can effectively "reverse a natural biological pathway" to generate valuable precursors like galactose from readily available feedstocks like glucose. This methodology creates a flexible platform for the efficient synthesis of tagatose and, crucially, opens the door to the biotechnological production of other rare sugars.

Many rare sugars, such as allulose and D-psicose, also possess unique health benefits and desirable sensory profiles but are similarly difficult and expensive to produce on a large scale. The success with tagatose provides a blueprint for developing robust, scalable, and cost-effective biomanufacturing processes for these compounds as well. This could unleash a new wave of healthier food ingredients, moving beyond the current limited palette of sugar substitutes.

From a sustainability perspective, biotechnological production methods offer significant advantages over traditional chemical synthesis or extraction from scarce natural sources. They typically involve milder reaction conditions, reduce the generation of hazardous waste, and can utilize renewable agricultural feedstocks, thereby lowering the overall environmental footprint of sweetener production. Economically, this innovation could foster the development of new industries and supply chains focused on sustainable biomanufacturing, potentially creating new employment opportunities and driving economic growth.

While the scientific breakthrough is clear, the journey from laboratory to widespread market adoption involves further steps. Long-term human clinical trials will be essential to fully characterize the sustained health impacts and optimal dosages of tagatose. Scaling up industrial production to meet global demand will require significant engineering and investment. Furthermore, navigating diverse international regulatory frameworks and educating consumers about the benefits of this novel sweetener will be crucial for its successful integration into the global food system.

In conclusion, the development of an efficient, scalable, and cost-effective biosynthetic method for tagatose production marks a pivotal moment in the ongoing quest for healthy sweetness. By combining the desirable taste and functional properties of sugar with a significantly reduced caloric impact and distinct health benefits, tagatose emerges as a compelling contender to reshape dietary patterns and improve public health outcomes. This biotechnological triumph not only promises a future where sweetness can be enjoyed without guilt but also lays the foundation for a new era in the sustainable production of rare sugars, with far-reaching implications for the food industry and global well-being.